Can You Use A Heat Press Printer On Polyester?

Over the past few years, using a heat press printer has become one of the most popular ways to print custom t-shirts. This has primarily been because it’s one of the easiest methods of doing so and comes with a significant amount of benefits.

However, many people have wondered whether they can use the process with certain fabrics. While many people know that the likes of cotton can be used with a heat press printer, many are unsure when it comes to polyester.

This uncertainty has been driven by the fact that heat press printing works better with certain fabrics than others. This is something that’s just as true with polyester. The main issue here is that polyester can be much more difficult to work with when using a heat press printer. This doesn’t mean that it’s impossible to do so.

Polyester can be heat-pressed at temperatures lower than 300°F. This synthetic fabric will be damaged by high temperatures, which will result in glossing or scorching. You may heat press on any polyester fabric by choosing the appropriate temperature setting, using low-temperature compatible transfers, and carefully timing the pressing.

It should be noted, though, that there are a few different things that you should be aware of when you’re using polyester with your heat press printer. By doing so, you’ll be able to ensure that the final design is a high-quality t-shirt.

Can You Heat Press Polyester?

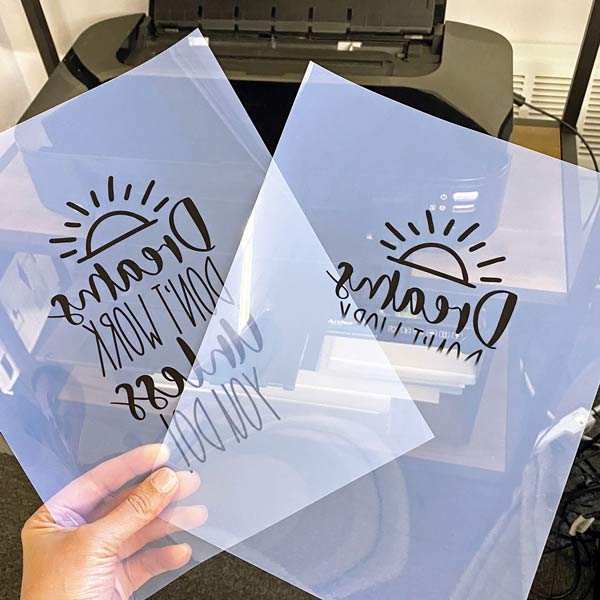

If you careful to the temperature of the heat press and the pressure used, you can use a heat press to transfer designs onto polyester fabric.Heat transfer printing transfers ink from a printed design onto your textile using pressure and heat. This procedure may also be referred to as “sublimation printing.”What’s so special about printing on polyester, then? The ink from the printed design is thermally transferred to the fabric during sublimation printing. Because poly is sensitive to high temperatures, this could be problematic.Polyester can be heated with a heat press, but you must be aware of the appropriate temperatures and equipment to utilize. If you don’t, you risk tearing the fabric.For instance, certain transfer papers are made to stick to the fabric even when it’s cold. You may produce your printed design with these low-temperature items without utilizing a high temperature that might scorch the fabric.

Tips For Using Heat Press Printing With Polyester

Polyester Fabric Comes in Different Types

Polyester is a synthetic fabric that is renowned for being strong and affordable. You should be aware that polyester exists in a variety of forms, the majority of which are heat-sensitive materials. Several fabrics made of pure and mixed polyester include:

- Acrylic

- Acetate

- Lyca / spandex / elastane

- Microfiber

- Nylon

- Rayon / viscose

- Poly blends

With all these different polyester types, can you print HTV on all of them? No. Polyester made of acrylic will melt at high temperatures. Also, nylon requires extra care when printing HTV on it. Always check the tag of the shirt or the product description of the shirt, on the type of polyester material used.

Check if the Shirt Is a Heat Sensitive Item

It’s usually wiser to be cautious and determine whether the shirt is made of heat-sensitive fabrics once you’ve examined the type of material used to make it. It’s possible that you should hesitate before pressing HTV on something that is heat-sensitive.Use an HTV that can be pressed at a lower temperature, preferably under 270 degrees Fahrenheit, if the shirt is designated as “sensitive to heat or heat-sensitive polyester.” If not, then HTV printing is good to go.Use heat transfer vinyl, which can be pressed up to 350 degrees Fahrenheit, if the shirt is not heat-sensitive.

Find The Right Temperature

Heat press printers normally use quite a high temperature, as this allows a design to stick to the fabric. This wouldn’t be possible if you were using a low temperature. However, this is something that you should keep an eye on when you first start using polyester.

This is primarily because it’s one of the more sensitive fabrics when it comes to heat and can react badly to too much of it; this is why it’s become somewhat well-known for being difficult to work with.

This is why you should pay a particular amount of attention to how hot your heat press printer is when you’re printing on polyester. Many experts have suggested that the 270 to 300 degree Fahrenheit range can be the most effective when it comes to the fabric.

It’s also been noted that you shouldn’t apply the heat for too long, as this can do just as much damage to your t-shirt as applying too much heat in the first place.

Here is a summarized table on temperature guide. To get the best guide on temperature on follow this article.

|

Type of Fabric |

Temperature |

Time |

|

|---|---|---|---|

|

100% Polyester |

270℉ |

10 Seconds |

|

|

100% Cotton |

380℉ |

Up to 15 minutes |

|

|

Polycotton |

340℉ |

10 seconds |

|

|

Triblend |

250℉ |

|

Use Thin Cover Sheets

When it comes to preventing your fabric or design from scorching or melting, there can be a variety of different factors to consider. There are also a few different ways to prevent it from happening, with the most notable of these being the use of cover sheets.

These are placed over the design and t-shirt and under the heat press printer and serve as something of a protective barrier between them.

Because polyester can be notoriously difficult to print on, then this is something that comes highly recommended. However, these cover sheets have also been known to stop heat from being transferred to the design.

This means that you’ll need to put a significant amount of thought into when choosing which cover sheets to use. Many designers have recommended using one of the thinner versions of the sheets, to begin with.

The exact thickness of the cover sheets you should use can vary greatly depending on what design and fabric you’ll be using. As such, there may be a certain amount of trial and error involved in the process.

Be Gentle

The amount of pressure you use during the heat press printing process can have a significant effect on the final t-shirt design. This is because too much pressure can end up creating a variety of heat marks on your t-shirt.

Because of that, you’ll want to apply as little pressure as possible when you’re printing on polyester. This is something that can be quite difficult to figure out, as you’ll need to apply a certain amount of pressure to apply the design.

With these two aspects in mind, you may need to go through a considerable amount of trial and error when you first begin printing your t-shirts. Once you’ve figured this out, however, you’ll be able to ensure that you’re able to apply the right amount of pressure almost every time.

How To Avoid Heat Press Marks On Polyester

Developing heat marks on polyester is one of the larger concerns when it comes to printing on polyester. They’re also something that the majority of designers will want to avoid, as it reduces the overall quality of the design.

Despite the problem being relatively common, there are no set ways to avoid them from developing. One of the easiest ways to minimize these marks is by ensuring that you aim for the lowest temperature possible while still being able to apply the design.

This might not always work, however, and your polyester t-shirt may still develop heat marks. Should this happen, then you should wait until the t-shirt cools down before doing anything; in some cases, the heat marks will disappear during this cool down.

If the marks are still visible after this, then you should wash your t-shirt, and this may get reduce the appearance of the heat marks, if not get rid of it completely.

In some cases, this may not get rid of the heat marks. If this happens, then you may need to start again with a new t-shirt and use a lower temperature during the printing process.

By focusing on each of the above areas, you’ll be able to ensure that your heat press printer doesn’t damage the polyester or the design that you’re printing. Using polyester has been one of the more difficult fabrics when it comes to heat press printing. This doesn’t mean that it’s impossible, as each of the above points illustrate.

However, if you’re looking for an easier way to create a custom t-shirt, then you might want to consider using the likes of cotton. This is because they can be much simpler to print on while also offering fewer problems throughout the process. When it comes to polyester, you should exercise care when during the printing process.

Tips for Heat Printing on Polyester

Here’s a quick brief of the things you need to know about printing on polyester.

Check The Level

If you want to print on any pre made item that time you will get the manufacturer’s label inside the product. In the level, you can usually find information about the fabric’s composition.

As you know exactly what fabric you are putting in your press. Now, you can set the temperature correctly for the product.

Test First

This is a good idea to put a test press on the spare scrap fabric before going to run a huge production.

But if you are on limit that time try to test the temperature on a small or hidden corner of the fabric.

You May also Read: How To Heat Press A Hat

When it Goes Wrong

Most likely, you’re asking yourself, “Okay, but what if things goes wrong?” The bad news is that while you can take sensible care to keep polyester from getting damaged, once it has, there isn’t much you can do to undo the error.Melting or scorching is the biggest risk you run when utilizing a heat transfer on polyester. There will almost probably be crinkly or glossy spots on the polyester if you press the design on the fabric for too long or with too much heat.You might try washing the cloth to see if that helps to reduce the crinkly appearance. On shiny spots, you might also try using a hard brush. But most experts agree that neither of these methods consistently produces results.In addition to the possibility of burning, colour migration can ruin your polyester print. When the ink on the cloth itself bleeds into the ink of your printed pattern, it’s called dye migration. Dye migration can be seen, for example, when you transfer a black-and-white photo design onto a hot pink t-shirt and find that pink splotches have crept into the printed image.Utilizing dye made for polyester printing should help to eliminate any dye migration problems. As the adage goes, an ounce of prevention is worth a pound of cure, so just be sure to conduct some research and acquire the right tools for your project!

Can You Heat Press Polyester and Spandex Blend?

If you take some precautions, you can heat press a polyester-spandex blend without damaging it. Yoga trousers and exercise tank tops are just two examples of the athletic apparel made from this popular material. It makes sense why you might wish to put entertaining graphics on such trendy apparel!But here’s the catch: due to the flexibility of the fabric, heating a poly-spandex blend may produce blistering or unsightly stretching and shrinking.Pre-shrinking the fabric and using a slightly lower temperature than you would for 100% polyester are two precautions you should take to prevent this.Put polyester through a wash cycle and a dryer cycle to pre-shrinken it. The fabric shouldn’t shrink in the press if you’ve already heated it in the dryer.

Frequently Asked Questions

Can you heat press 100 percent polyester?

Yes, you can heat press on 100% polyester. Lower temperatures and longer press time is recommended when you heat press polyester with HTV. The higher temperature on the heat press machine may cause the fabric to scorch.

What temperature do you press HTV on polyester?

The recommended heat press temperature for HTV on polyester is lower than 270 degrees Fahrenheit. Do not use high temperatures on polyester as this may cause burn marks or discoloration.

Conclusion

People over the years have tried to apply designs or logos through a heat press on polyester garments, which is very difficult. Although that doesn’t mean that it is impossible.

If you take the option of using a more suitable material – like cotton – this will make your life easier and give you quicker results.

Polyester can be a tricky fabric to use in heat press. As polyester are designed for lower temperatures and be as gentle as possible.

It does not matter how many times it takes as long as the results you are trying to achieve happen that is all that matters.