PLA vs ABS – What’s The Difference?

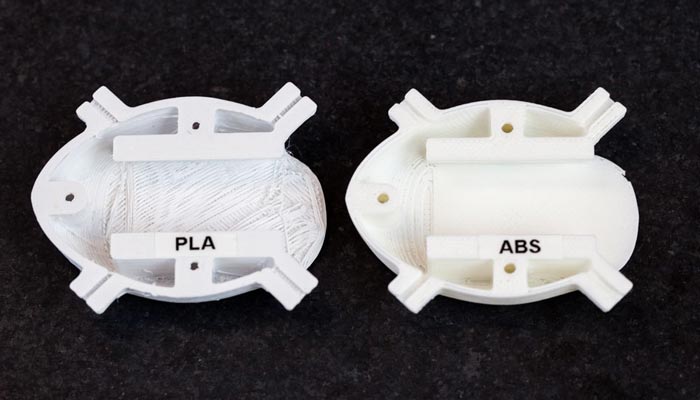

3D printers have become more popular in recent years, with a wide range of prices and capabilities on the market. One of the most important choices you’ll make when buying a 3D printer is what type of filament to use. 3D printing filaments are made of thermoplastic materials. The two most common types of 3D printing filament are PLA and ABS. So, what is the difference between PLA and ABS? They’re interchangeable but the reality is there are significant differences between the two.

What Is PLA?

Polylactic acid, or PLA, is a type of plastic made from renewable resources like corn starch. Unlike other types of plastic, PLA is not derived from petroleum. PLA is biodegradable and compostable, making it a more environmentally friendly option than traditional plastics. PLA can be used to make a variety of products, including food containers, packaging, and utensils.

The glass transition temperature in PLA is quite low. The temperature at which the filament becomes bendable is roughly 65 degrees for PLA. The good news is that printing with this material doesn’t require nearly as much heat or power. The bad news is that PLA cannot be used to print anything that must endure the heat for any significant amount of time.

Now, PLA is rather sticky when heated since it is created with natural sugars. This is beneficial because it keeps your models from shrinking while you print and helps them adhere to the print bed. Additionally, the sugars emit an almost honey-like scent that adds a little extra pleasure to every print session.

Feature of PLA

- Polymer density: 1.21-1.25 g/cm3.

- Tensile toughness: 21-60 MPa.

- Tensile modulus: 0.35-3.5 Grade point average.

- Ultimate strain: 2.5-6%.

- Details tensile strength: 16.8-48.0 Nm/g.

- Particular tensile modulus: 0.28-2.80 kNm/g.

- Glass transition temperature level: 45-60 ℃.

- Melting temperature: 150-162 ℃.

What is ABS?

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer. It is a copolymer made from the monomers acrylonitrile and butadiene. ABS is a tough, rigid plastic with high impact resistance. It is used in a wide variety of products, including LEGOs, automotive parts, and electronic devices.

At roughly 105°C, ABS has a greater glass transition point than PLA. This indicates that it’s a superior option for printing heat-sensitive products. Make a gearshift knob that won’t melt in your automobile on a hot day, for instance.

Another aspect contributes to ABS’s popularity as a standard printing medium. It is quite tough. ABS is corrosion-resistant and much more likely to stretch than to break. Because of its incredible tensile strength, it’s a fantastic option for anyone wishing to sand, polish, or glue the end product.

Feature of ABS

- Density: 1.02-1.21 g/cm3.

- Glass transition temperature: 90-102 ℃.

- Young Modulus: 1.79-3.2 Grade point average.

- Toughness: 200-215 J/m.

- Strength at Yield (Tensile): 29.6-48 MPa.

- Strength at Break (Tensile): 29.8-43 MPa.

- Stiffness (Flexural Modulus):1.6 -2.4 Grade point average.

- Hardness Shore D: 100.

- Elongation at Return: 1.7-6%.

- Elongation at Break: 10-50%.

What’s the Difference Between PLA and ABS: Summary

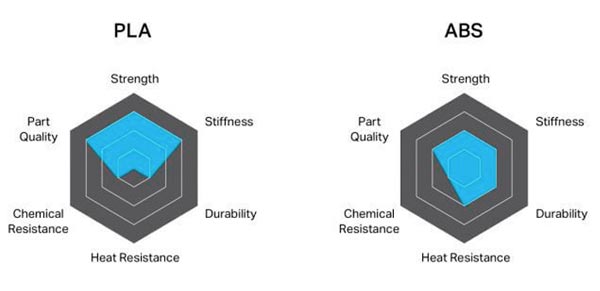

PLA and ABS have many differences in unique tensile strength, density and ideal applications. The table below compares the key material properties of PLA and ABS filaments.

| Properties* | ABS | PLA |

|---|---|---|

| Tensile Strength** | 27 MPa | 37 MPa |

| Elongation | 3.5 – 50% | 6% |

| Flexural Modulus | 2.1 – 7.6 GPa | 4 GPa |

| Density | 1.0 – 1.4 g/cm3 | 1.3 g/cm3 |

| Melting Point | 200 ℃ | 173 ℃ |

| Biodegradable | No | Yes, under the correct conditions |

| Glass Transition Temperature | 105 ℃ | 60 ℃ |

| Spool Price*** (1kg, 1.75mm, black) | $USD 21.99 | $USD 22.99 |

Main Differences Between ABS and PLA

The impact strength is the primary distinction between PLA and ABS. The first one is thought to be more resilient to stress and more durable than PLA. Additionally, it is more dependable in terms of long-term wear and tear. However, PLA is less hazardous and simpler to print than ABS.

It requires lower temperatures (both extruder and printing bed) and doesn’t need a closed printing space. When it comes to availability and color options, PLA is the most prevalent filament, so if you want to print multi-color display models, this material is definitely better.

When it comes to nozzle temperature, PLA is not picky and begins to melt at about 170°C. This is useful if all you have is a cheap 3D printer that runs at low temperatures. Additionally, although having a heated table makes things simpler, you don’t need one. However, because of this property, a PLA sculpture may distort if left in direct sunlight.

PLA is not as sensitive to temperature changes as ABS, and this means less problems with warping. Polylactide is also better for detailed models and is more suitable for 3D printing bridges and overhangs without support.

ABS is more resistant to elements. It can withstand more pressure and heat than PLA and therefore is used for parts and models that will be exposed to a lot of wear and tear.

| PLA | ABS | |

| Temperature (Extruder / Table) | 200-230°C / 60°C * | 220-250°C / 80-100°C * |

| Impact strength | 16 kJ/m2 * | 20 kJ/m2 * |

| Vicat softening temperature | 55°C * | 94°C * |

| Printer space | Open | Closed |

ABS and PLA Prices

Prices for PLA and ABS are comparable, ranging between $25 and $35 per kilogram. High-quality 1 kilogram spools of ABS and PLA filament are available from Zmorph for $34. By using less expensive, inferior materials, you run the risk of having your extruder clog and having prints of poor quality.

Differences in Post-Processing

Despite the fact that both materials are polymers for 3D printing, there are some distinctions between PLA and ABS’ post-processing. Commence with polylactide.

If you don’t want to use chemicals, you may use THF (Tetrahydrofuran) or ordinary sandpaper to smooth the surface of PLA prints. In order to gradually disintegrate the surface and conceal layers, some people also utilize heat guns.

Acetone is the ideal post-processing solvent for ABS, though. A detailed tutorial on post-processing ABS prints can be found on our blog. Check it out without a doubt. In comparison to PLA, ABS is generally thought to be simpler to post-process. Acetone should only be used if you want the model to be very smooth because often simple sanding is sufficient.

How Fast can You Print with PLA and ABS?

ABS and PLA print at almost the same rates. As a result, you can transition between materials without having to adjust the speed settings on your FDM machines. Although some operators have printed PLA at speeds of exceeding 150 mm/s, the usual speed is by no means a cap. For PLA, printing at 60 mm/s is relatively normal. ABS may also be printed at the same speed, however this material prints more accurately between 40 and 60 mm/s.

Are PLA and ABs biodegradable?

PLA is stable under normal air conditions, however it degrades in industrial composters in 50 days and in water in 48 months. Although ABS cannot degrade, it may be recycled. Due to this, manufacturers frequently utilize PLA to create products for the food service industry, however we strongly advise you to obtain safety confirmation from filament makers.

Conclusion

It is important to know the difference between PLA and ABS filaments when 3D printing. PLA is a biodegradable plastic made from cornstarch, while ABS is a petroleum-based plastic. Each has its own advantages and disadvantages. PLA is less smelly and requires less heat to print, but it is not as strong or durable as ABS. ABS is more difficult to print with because it requires higher temperatures, but it is stronger and more flexible.